Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

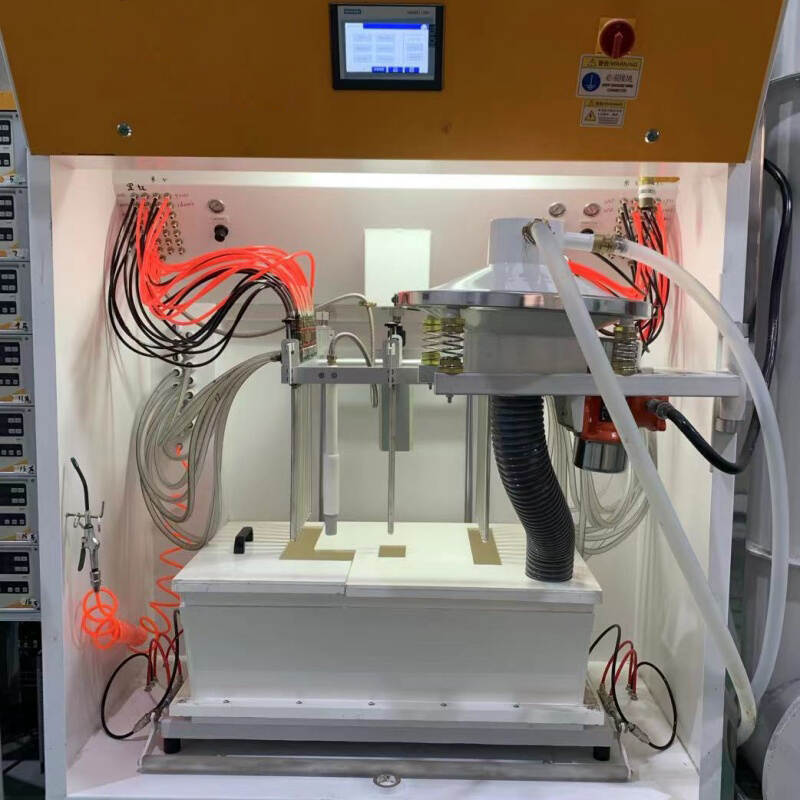

Powder Feeding Center

The Powder Feeding Center is an advanced, automated powder supply system designed to serve as the core of an industrial powder coating line. With precision control, high-efficiency powder handling, and support for quick color changes, this intelligent system ensures stable powder output, minimal downtime, and optimal spraying performance.

Built to integrate seamlessly with cyclone recovery systems and multi-gun configurations, the Powder Feeding Center dramatically improves material utilization, color change efficiency, and process automation, making it an essential tool for high-throughput, multi-color powder coating environments.

Key Features & Benefits

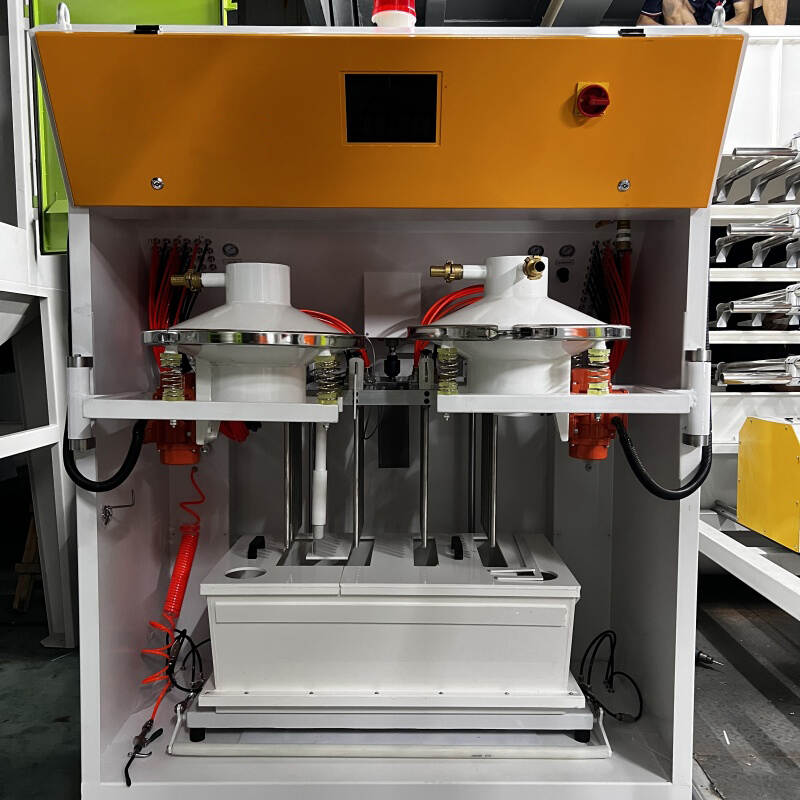

Efficient and Centralized Powder Management

Equipped with a Powder Pump Installation Bracket that accommodates up to 14 sets of powder pumps, supporting large-scale and high-speed operations. Integrated Powder Transfer System enables recovered powder from the cyclone to be automatically delivered to the powder center for re-use.

Automated Control & Monitoring

The Touch Screen Electric Control System offers intuitive operation, enabling real-time adjustments, performance tracking, and smart diagnostics for seamless powder coating management.

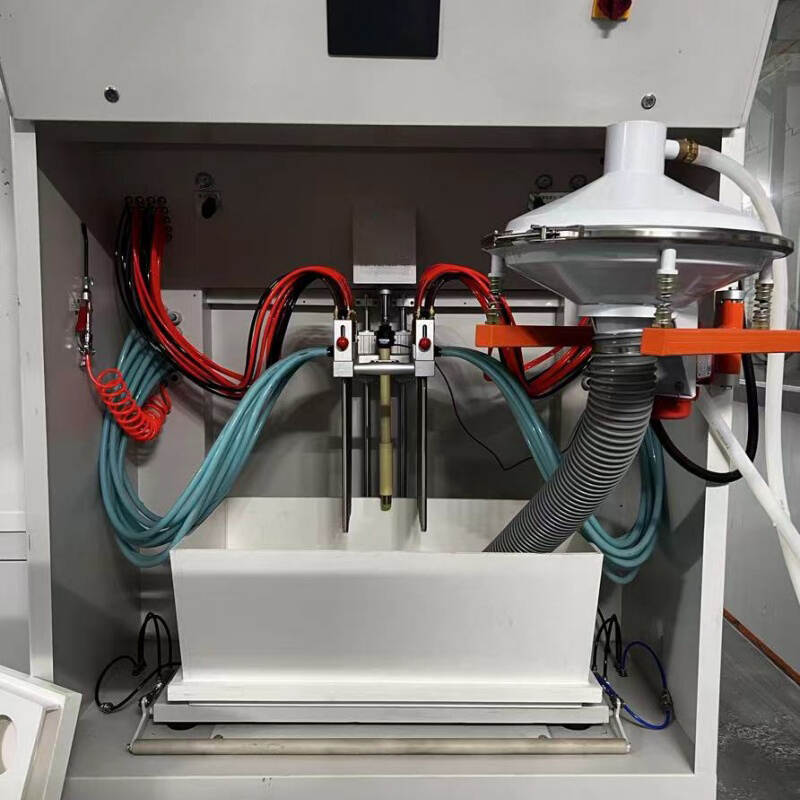

Precision Powder Management

An Automatic Movement Control Cylinder optimizes the powder pump bracket’s position for peak efficiency and easy maintenance. Integrated Powder Bucket Detector and Level Sensor prevent overfills or shortages, ensuring consistent material supply.

Quick Color Change Design

Features a high-performance engineering plastic fluidized powder bucket, enabling fast color switching with minimal contamination risk.

Automated Cleaning Efficiency

The built-in Automatic Cleaning System thoroughly purges the powder suction pipe, pump, and pipeline walls—slashing downtime and eliminating cross-color contamination.

Vibration and Clamping System for Consistent Flow

The vibration platform ensures uniform powder fluidization, improving transfer efficiency and preventing blockages. Automatic clamping device secures the powder bucket, streamlining setup and ensuring consistent contact with system inlets.

Precision Screening for Superior Coating Quality

Features a quick-release integrated electric powder sieve (80~100 μm aperture) that filters out impurities before powder enters the supply pipeline. Promotes higher surface finish quality by ensuring only fine, clean powder reaches the spray guns.

Advantages

- Supports High-Speed Coating Lines

- Ideal for Multi-Color Production with Quick Color Change

- Enhances Powder Recovery and Reuse Efficiency

- Reduces Manual Labor with Full Automation

- Improves Surface Coating Quality by Eliminating Contaminants

- Ensures Reliable, Consistent Powder Flow to All Spray Guns

Integration Capabilities

This Powder Feeding Center is designed to integrate seamlessly with:

- Large Cyclone Powder Recovery Booths

- Automatic Reciprocators

- Electrostatic Powder Coating Guns

- Industrial PLC or Centralized Control Systems

- Multi-Gun or Multi-Line Spraying Configurations

Whether operating a single production line or a complex system with multiple color changes per shift, the Powder Feeding Center serves as the nucleus of efficient powder handling.

Application Scenarios

- Aluminum Profile Coating Lines

- Automotive Frame and Part Finishing

- Home Appliance Metal Coating

- Tool and Hardware Finishing Plants

- Steel Furniture and Cabinetry Production