Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

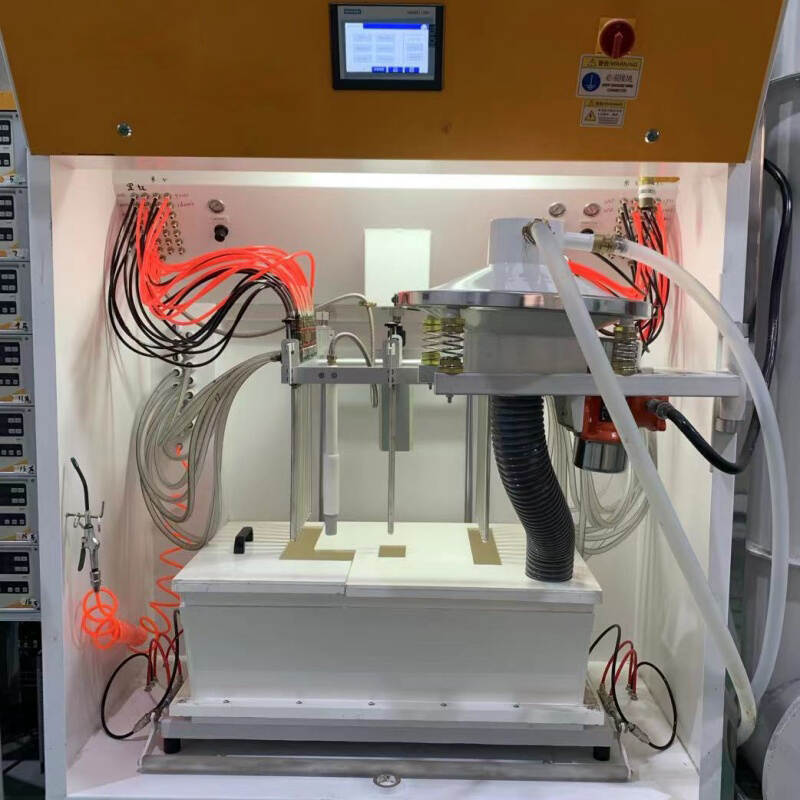

Automotive Parts Powder Coating Line

The automotive industry demands coatings that are not only visually appealing but also highly durable and performance-driven. Our Automatic Coating System for Auto Components is built specifically to meet the rigorous standards of automotive manufacturing, offering high-speed, uniform, and corrosion-resistant finishes for both internal and external car parts.

Whether you are coating engine brackets, shock absorbers, wheel components, or interior trim parts, this fully automated system delivers stable quality, consistent film thickness, and excellent production efficiency—helping you meet OEM and Tier 1 supplier standards.

Key Features and Benefits

Designed for Automotive Parts

Suitable for a wide range of components including chassis parts, engine parts, decorative trims, and more.

Fully Automated Workflow

From pre-treatment to spraying and curing, all steps are integrated to reduce labor and ensure uniform quality.

High Transfer Efficiency

Advanced spray guns and intelligent control systems minimize paint loss and ensure precise application.

Corrosion and Chemical Resistance

Delivers strong adhesion, long-term durability, and protection against heat, oil, and road salts.

Eco-Friendly Options Available

Powder coating or water-based spray options to reduce environmental impact and meet global compliance.

Integration Ready

Easily connected to robotic arms, conveyorized loading, or MES (Manufacturing Execution Systems) for Industry 4.0 environments.

Application Scenarios

This system is widely used for coating the following auto parts:

- Engine brackets and mounts

- Wheel hubs and suspension arms

- Door handles and mirror covers

- Seat frame components

- Wiper motor covers and other small casings

- Interior trim brackets

- Battery housing (for EVs)

The system supports both mass production and custom batch processing, making it ideal for automotive OEMs, parts suppliers, and contract manufacturers.

Customizable Options

To meet different customer and factory requirements, we provide:

Layouts (U-type, linear, L-type)

Robotic spray integration for complex 3D shapes

Multi-color or multi-layer coating support

Powder recovery system (cyclone or filter cartridge)

Adjustable curing oven temperature and length

Turnkey solutions with MES/SCADA integration

Why Choose Our Coating System

- Automotive-grade build and precision

- Modular structure, scalable for growth

- Global installation and training support

- Compliant with ISO/TS 16949 quality standards

- Long-term spare parts and maintenance service

Frequently Asked Questions

Q: Can this system meet automotive OEM quality standards?

A: Yes, our systems are designed to meet stringent surface treatment specifications including film thickness, adhesion, and corrosion resistance.

Q: Does it support both small and large parts?

A: Absolutely. We customize the conveyor hooks, jig design, and booth size according to your parts' shape and size.

Q: What if I need both powder coating and wet spraying in one line?

A: We offer hybrid lines that combine both processes or install them in parallel for flexible production.

Q: How long is the curing process?

A: Depending on coating type, curing takes around 15–30 minutes at 160–220°C.