Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

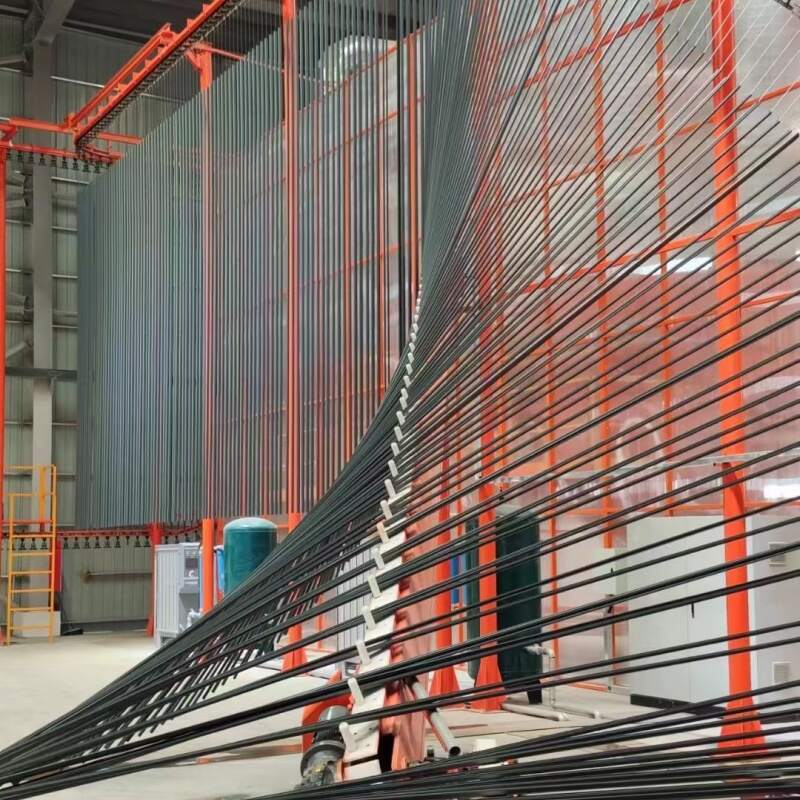

Aluminum Profile Vertical Spraying Line

When it comes to aluminum extrusions used in architecture, windows & doors, or industrial applications, surface quality and corrosion resistance are non-negotiable. Our Intelligent Multi-Station Vertical Coating System for Aluminum Extrusions is specifically designed to optimize coating efficiency, save factory space, and ensure consistent finish quality.

This vertical powder coating line features a hanging conveyor structure, integrated with automated multi-station spraying, rapid color change, and energy-efficient curing technologies. Ideal for high-volume aluminum profile manufacturers, this system brings your coating operations into the smart era.

Key Features & Advantages

Vertical Layout Saves Space

The vertical hanging conveyor design reduces floor space by up to 70% compared to horizontal lines—ideal for space-limited facilities.

Smart Recognition with Multi-Station Spraying

Equipped with intelligent product recognition to control spray parameters per item, enabling precision coating and minimizing powder waste.

High-Speed, High-Throughput Production

Capable of coating 8–10 profiles per minute, meeting the needs of large production volumes with ease.

Quick Color Change System

Supports rapid color switching (10–15 minutes) with an integrated automatic cleaning unit, reducing downtime and improving flexibility.

Fully Automated Control System

PLC + HMI touchscreen interface with real-time monitoring, formula management, and fault alerts ensures streamlined operation.

Eco-Friendly and Energy-Efficient

Equipped with powder recovery system and heat recycling curing oven to lower operational costs and meet environmental standards.

Applications

- Architectural aluminum profiles (windows, curtain walls, railings)

- Industrial extrusions (radiators, tracks, structural components)

- Decorative trims and custom aluminum parts

- Furniture, shower rooms, and home improvement aluminum items

Optional Add-ons

Programmable moving spray guns (up/down + swing)

Centralized powder supply & color change system

Vision-based product detection & auto color matching

MES system integration for smart factory management

Online coating thickness detection & data traceability

Why Choose Us

- Years of experience in vertical powder coating line engineering

- Trusted by top aluminum profile manufacturers globally

- Reliable equipment performance with fast technical support

- Overseas installation and remote service available

- Customizable layout and process design per factory needs

Frequently Asked Questions

Q: Is this vertical system suitable for small or medium-sized factories?

A: Yes. It saves floor space and is scalable for both medium and large production capacities.

Q: Can it handle multiple colors in small batches?

A: Absolutely. Our rapid color change module is designed for flexible batch production.

Q: Will there be coating blind spots or uneven thickness?

A: No. Multi-angle, multi-gun coordination ensures uniform coating with high precision.

Q: How long does installation and commissioning take?

A: Typically 3–5 weeks depending on plant conditions and customization.